Crafting Perfection: The Quartz Countertop Process

Hello! Ever wonder what quartz countertops is made of? How These Gorgeous Counter Tops Are Made Start To Finish Today,.userdetails. The types of materials they use, the steps that are included in developing quartz countertops, and the machines utilized to assist them in their process; how assessors test each countertop for quality control.

Hello! Ever wonder what quartz countertops is made of? How These Gorgeous Counter Tops Are Made Start To Finish Today,.userdetails. The types of materials they use, the steps that are included in developing quartz countertops, and the machines utilized to assist them in their process; how assessors test each countertop for quality control.

Process of Making Quartz Countertops

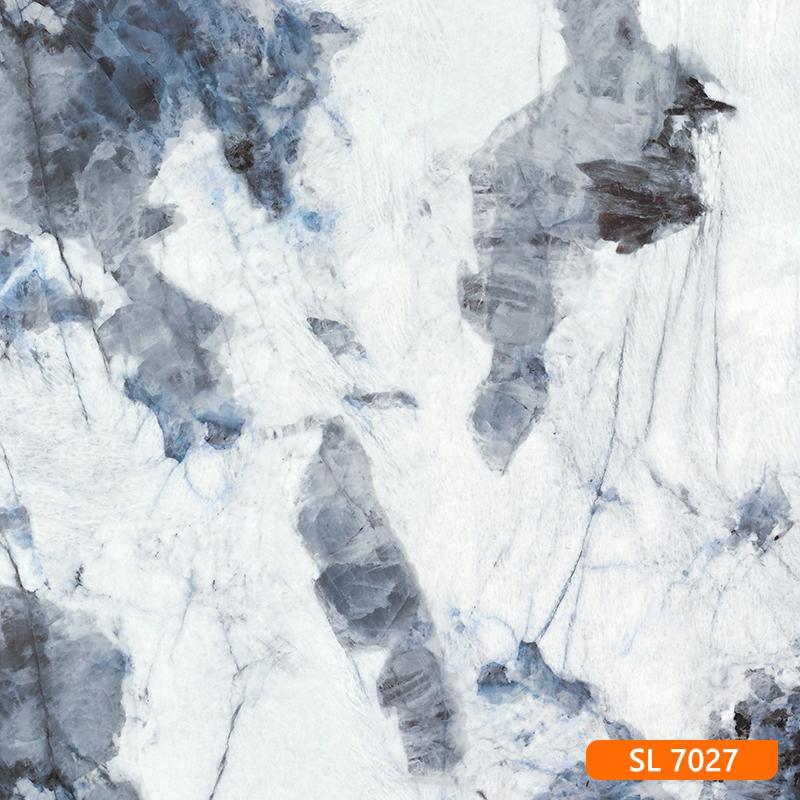

A natural substitute for a non-repair material is quartz, which comprises quartz kitchen countertop. This stuff makes up one of natures hardest substances. Manufacturers have begun to create these countertops by blending quartz with assorted significant TRANSSTONE resources. These types of sealer are made up from resin, matte or glossy pigments for color and design on countertops tumbled glass is sometimes incorporated as well to give counters a slight sparkle effect that will make it different.

You then mix all these things and the next thing you do is pour this mixture in a mold which looks like kind of big container that gives shape to your countertop. The mixture must be smooth and free of air pockets. Air bubbles can occur and this will make those points on the countertop sort of weak. Once the pour is made, you press the mould down very firmly to get rid of air pockets. This rolling helps get any air bubbles out and ensures a flat, sturdy counter.

When the mixure is in compact mode using somekindy of mold, time to put it into the oven for a bake. Now this seems especially interesting as a heating process - kind of like baking a cake!!! Once heated, this mixture will solidify and be very durable. The countertop CONCRETE has to then be cooled once it is heated up correctly. After it is cold, the countertop is polishing to leave a shiny and good looking offering that both looks great,and also easiler to clean.

How to Make Striking Polished Quartz Panels

The process of creating smoothed out shiny quartz surfaces is a practiced art that takes care and incredible detail. Now when it comes to the best results, every single detail counts and a good craftsman (i.e., someone skilled in their works) must be mindful of that. The first step is to make sure the mold surfaces are flat and smooth. Bumps on the mold, or an uneven surface to the mold will show up in your countertop.

The craftsman then pours the mixture into a mold, making sure no air bubbles are trapped within it. It is a delicate process with even the slightest mistake can result in how your final product turns out. Once the countertop is compressed, it's important to keep them at a proper temperature as they go through the heating process. If too hot, the countertop could catch fire; If too cold, it may not set properly. Last, during the countertop polishing again requires CALACATTA a craftsman with very patience to not make any scratch. Even the smallest scratches can appear remarkable when they damage that big finish.

How to Make Quartz Countertops - The Tools & Steps

All the steps in making a quartz countertop are important, as well as using special instruments to guarantee you will have it done properly. The Process Step-by-Step

Resin and Pigment Mixing: The first step in the process is to mix quartz with resin along with color pigments, into a large powerful mixing machine. This machine makes sure that the solution is mixed properly, which further assures a same colour and texture all over (even in hair).

Pouring (after the mix is ready, it is poured into a mold) Typically the mold is also covered with a plastic material to help ease in removing it from the top once done and has cooled.

Squeezed: The pump has been sawing and separated, the fluid then compact isolated from any bubbles or tight. Mark this step because it plays a crucial role in presenting the uncomplicated and seamless face on the countertop.

Curing: The countertop is placed in a high-temperature oven for several hours to accelerate the hardening process. This curing time is a very important step because it hardens up the counter so that we can install or place anything on top of it.

Cutting and Finishing - Once the product has cured, it is cut to size & polished. Aluminum is then polished to make a shiny smooth surface that looks and feels good.

The items that are required for this process include mixing machines, molds, compressors which help to apply pressure when needed, ovens (to give the necessary heat influences), and finally polishing tools will definitely provide it with a better shine. Every tool serves a unique purpose and must be used correctly in order to construct the countertop in an exceptional manner.

Quartz Countertop Production and Quality Measurement

Quality control is extremely important to quartz countertop manufacturers. They follow great rules and regulations to make sure that every countertops are of maximum top-ranking quality. And these are some of the other ways that they will ensure the countertops at of adequate quality.

Selecting Materials: The skilled artisans choose only the finest natural materials, resin and colorants to craft top grade countertops.

Multiple tests: They are experimenting with the manufacture of the cloth. By measuring the batch before it gets poured, observing how well it compresses or watching its temperature during curing.

Quality Review: The final product is carefully inspected after the completion of Coral Gables Kitchen and Bath work. The experienced craftsmen then check over the finish to ensure they are perfect and blemish-free, examining each countertop with an eagle eye for any imperfections, scratches or flaws that might not meet those incredibly high standards.

Lastly, many quartz countertop companies have warranties with their customers. It ensures that if there is any issue in the countertop because of manufacture defect then manufacturer will help repair it or change without asking anything from customer

Conclusion

So there you have it, anyway that was just a few uses for ALL quartz countertops in the kitchen and bath!! The process of making this countertops is very specialized and should be performed by professional experts using custom tools. Manufacturers can make sure every single countertop meets high quality standards by following stringent quality rules and measures. Final Thoughts: We hope this gives you a better sense of how quartz countertops are created, and the craftsmanship that goes into making each one!

Comments

Post a Comment