The Ultimate Guide to Mold and Die Casting Suppliers

The manufacturing of articles depends mainly on molds and die casting. To make the things very handy and smooth, Molds along with Die Casting offers you all necessary information. With this article, we will help you to understand what they are and why they matter in the manufacturing of all things. We will also explore where you can find suppliers online, how to locate them and what to consider when selecting the right supplier (as well as useful tips on communication), real ways of authenticating product quality.

The manufacturing of articles depends mainly on molds and die casting. To make the things very handy and smooth, Molds along with Die Casting offers you all necessary information. With this article, we will help you to understand what they are and why they matter in the manufacturing of all things. We will also explore where you can find suppliers online, how to locate them and what to consider when selecting the right supplier (as well as useful tips on communication), real ways of authenticating product quality.

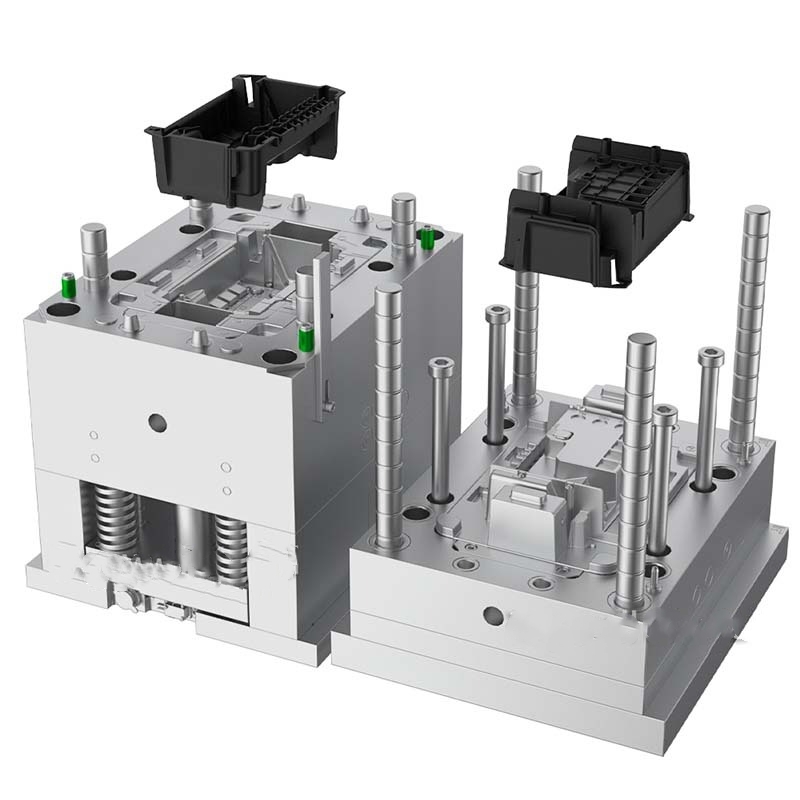

Molds and Die Casting

Molds are special tools that enable shaping of materials like plastic, metal or glass into desired shapes. They are employed in industries ranging from toys to car parts. MoldsParts of a MoldA mold consists the following kinds of parts: CORE:Cavity The Core: This Mold is the inside of your mold while the cavity for it makes up what seems to be (in everyday words) everything else around that shape you want. The material flows into the mold and conforms to the shape of the cavity, before hardening in its final form.

Definition: Die casting is the method of forming metal parts. Hot liquid metal is poured into a cast in die-casting. This hot metal is then cooled in the mould so as to solidify it. The finished part is then removed, cleaned up and machined to final specifications. The major types of die casting process are the hot and cold methods. Hot die casting operates on temperatures, whereas cold-diecasting proceeds at comparatively reduced warmth. Every method can have its own use and benefits.

Finding Good Suppliers Online

Searching Online for the Leading Mold and Die Casting Suppliers As the Internet is a very good solution, you can conveniently locate dozens of mold production plants and die casting companies. You will be able to read reviews as well as comments from other Plastic Injection Molding consumers who have used their waste removal services. These reviews also allow you to gain an idea of the reputation and quality product level from supplier side. Take the time to find a supplier that you can trust and meet your desired capabilities.

Matters To Consider When Choosing Suppliers

So what factors should you consider when selecting a mold and die casting supplier? Before everything else, they need to ensure that their products are high quality. You are looking for a supplier able to meet the production of high-quality molds and die casting parts that suit your standards. Second, check their prices. Then find a supplier with fair and competitive pricing that you are able to pay for. Third of all, think about just how lengthy they take to get the products over to you. You need your products delivered in a timely manner so that nothing slows you down.

Tips for Talking to Suppliers

When dealing with mold and die casting suppliers, you can consider these tips. Define Your Needs And Requirements First This will avoid any Metal Stamping Mold discrepancies and the supplier knows what you wants, same as towards your behalf. Secondly, the conversation moves to money and timeline of when you will get all those goods. These specifics should be decided early on. 3) Last but not least, always ask for samples so you can test and see the quality of their products. This helps to ensure you will get what a person pay for. Finally, in the negotiation keep your options open for just a win-win solution. Both parties may have something to compromise on for better working relations.

Making Sure Quality is Good

Mold and die casting is a very important process that involves quality control. This not only makes sure that the final product is high quality but also meets customer expectations. A quality control checklist is a great way to reduce this risk. It should be a complete checklist that includes all the key steps to test quality during production. It will also detail the steps you need to take if something goes wrong during this procedure. With a focused plan, you can avoid most of these problems and keep your standards high.

Finally, molds and die casting are necessary production steps in a wide range of industries. Hopefully, at this point you have a basic understanding of Mold & Die casting. You also learned how to find good suppliers online, how to choose them taking into account a set of important aspects such as talking with the supplier and reading reviews on his profile, in addition many other care (here you learn several ways that are actually very easy) make sure you do not hurt yourself ) for product quality. By applying these tips and rules, you will be able to filter a supplier that can cater for your needs while producing great molds &die casts. This will teach you the projects and also make sure that your manufacturing does not fail.

Comments

Post a Comment